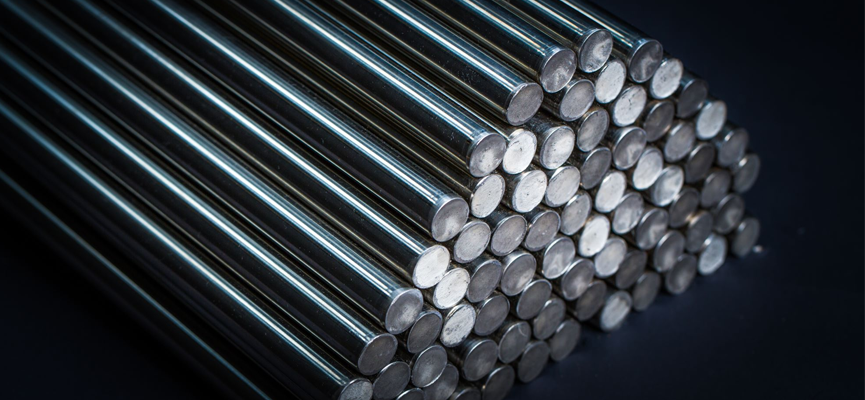

Carbon Steel Wire Rods

in various sizes can meet structural and mechanical requirements. It is

ideal for manufacturing, construction, and repair work. It is also used

to make axles, springs, and other mechanical parts that require strength

and stability. They balance ductility and strength and have good wear

resistance. They are used in forging and for large industrial and

automotive components. High carbon steels contain approximately

0.6–0.99% carbon. They are very strong and are used for springs and

high-strength wires.The Hot Rolled Alloy Steel Round Bars are utilized

in numerous additional applications and equipment, including brake dies,

trim dies, bolsters, gears, stubs, reamer bodies, tool holders, chain

links, fixtures, valves, spindles, and couplings.