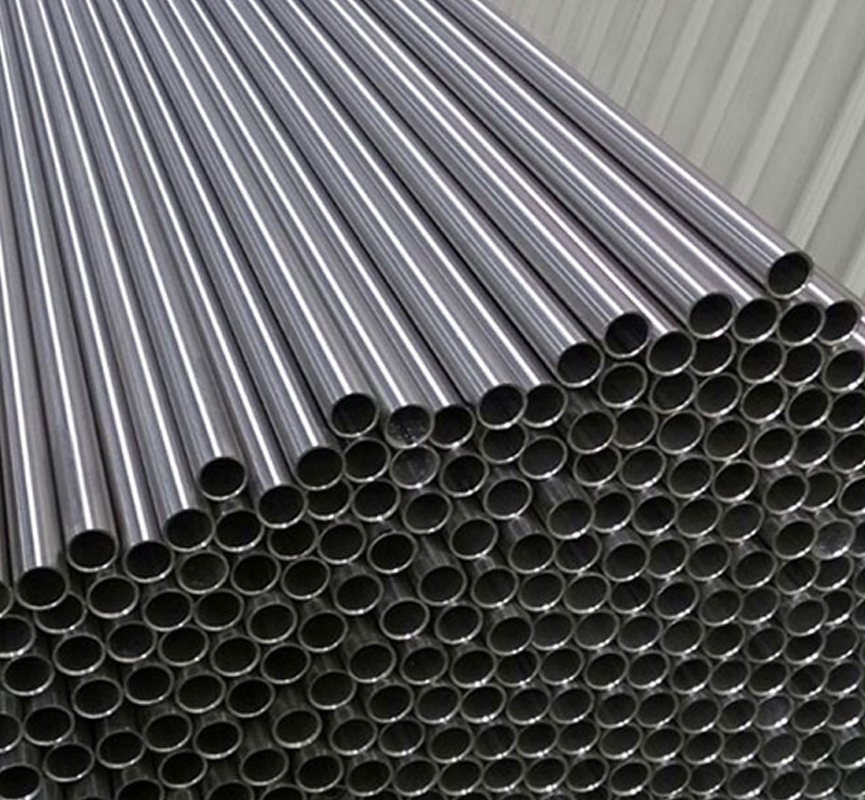

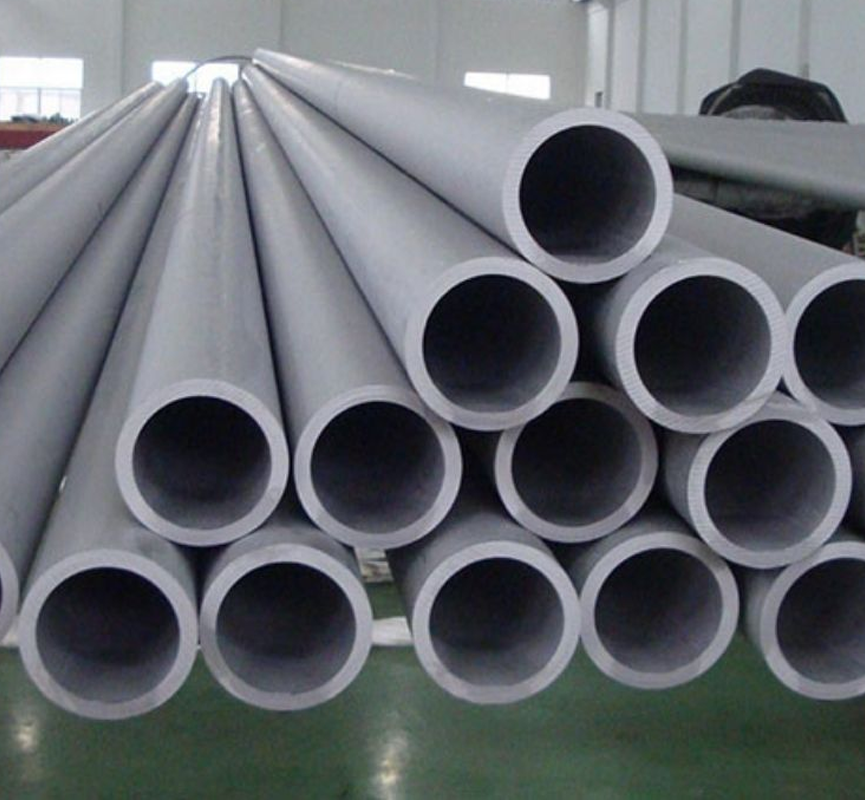

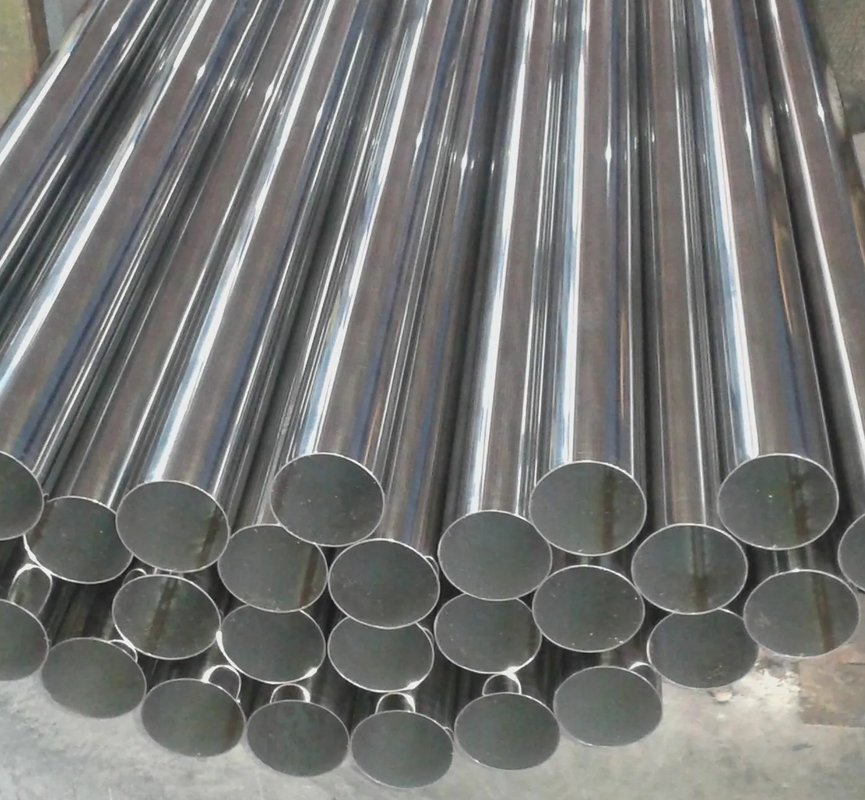

Pipes & Tubes

Tubes are used in applications such as medical devices that require a precise outside diameter. The outside diameter is important since it will indicate how much it can hold as a stability factor. Pipes are used for transporting gasses or liquids making it important to know the capacity. A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.